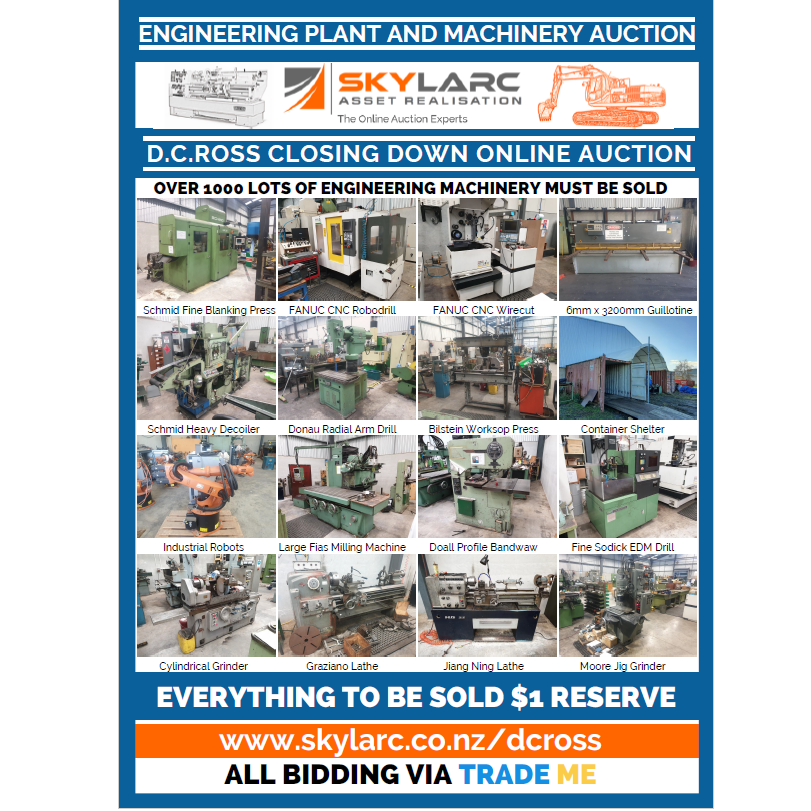

Established in 1963 D.C.Ross have provided precision engineering services to the automotive manufacturing sector, they produced pressed components for vehicles including brake components and seat belt parts. With the ceasing of vehicle manufacturing in Australia their main source of revenue was removed. The decision was made to close the business and sell off the plant and machinery of the business. Machinery included two operational Schmid fine blanking presses, vertical machining centres, a wide range of grinders and tool cutters, a Fanuc wire cut machine, several EDM machines along with lathes, mills and presses. Skylarc were contacted to provide a valuation of the plant and provide a plan to maximise the return on this machinery.

The Challenge

Established in 1963 D.C.Ross have provided precision engineering services to the automotive manufacturing sector, they produced pressed components for vehicles including brake components and seat belt parts. With the ceasing of vehicle manufacturing in Australia their main source of revenue was removed. The decision was made to close the business and sell off the plant and machinery of the business. Machinery included two operational Schmid fine blanking presses, vertical machining centres, a wide range of grinders and tool cutters, a Fanuc wire cut machine, several EDM machines along with lathes, mills and presses. Skylarc were contacted to provide a valuation of the plant and provide a plan to maximise the return on this machinery.

The Process

Skylarc were asked to value the Mosgiel based plant and machinery and provide a proposal for it’s sale. An onsite Trade Me event would provide the largest possible audience so an event was proposed at the premises in Mosgiel. Having the plant and machinery displayed in its working environment gives buyers confidence around the condition of the machines and saves decommissioning and transport costs. Working with D.C.Ross’s team, machines were cleaned, decommissioned and accessories, parts and manuals were organised and displayed with machines. A local crane company was contracted to provide nationwide shipping costs for the large machines to open up the potential audience to all of New Zealand. Once cleaned and tested, machinery was photographed, tested and detailed descriptions outlining condition and specifications were created. The auction set up took three weeks; 1024 lots were photographed and described. Video footage of machinery operating was included where possible for workshop machinery and their videos uploaded to YouTube for inclusion in the Trade Me listings. The auction ran for 12 days, with one third of the auction ending each night between 6pm and 10pm over three closing nights. This ensured that buyers could bid on multiple items at once. Viewing was held at the site for two days to give buyers the opportunity to see the machines, increasing buyer confidence and financial return as a result.

Marketing

A comprehensive plan to sell all assets via an online Trade Me event was produced backed by a detailed marketing plan incorporating display advertising on Trade Me, a targeted Facebook campaign, industry email outs, and advertising in the major Dunedin papers.

The Results

Total sales exceeded the valuation in excess of 100% with turnover significantly above expectations. The large number of high quality lots bought a very large online audience and some impressive financial results. Total individual people who watched at least one lot in the auction: 8,853; total unique bidders 1,710; total unique buyers 375. Of the 1044 lots in the auction over 450 were couriered outside of the Dunedin region, showing the importance of opening up the auction to a nationwide audience.

To ensure a safe and controlled removal process, three collection phases were run, firstly for small items collected by hand, secondly for medium sized machines once all of the small items were gone and finally for large machinery that required heavy lift equipment and specialist decommissioning teams. Decommissioning and removal was a major task with three weeks of machinery removals. Skylarc also ran both a manual Covid 19 register and the government’s QR code system.