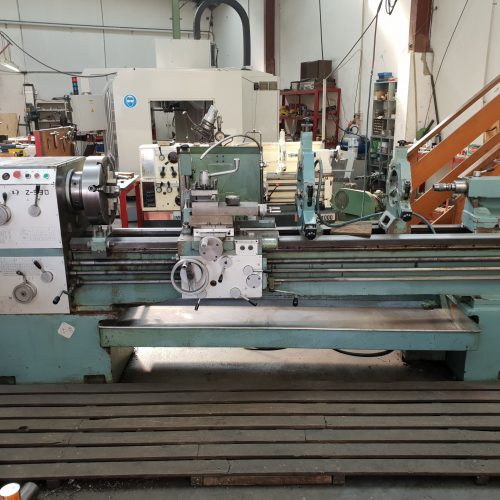

Mark Richardson Engineering was a well known local engineer manufacturing forklift mounted reinforcing steel lifters along with providing a wide range of precision engineering services. After a long and successful career Mark decided it was time to retire and spend time with his wife and family. Skylarc we’re assigned the task of maximising the return on Marks machinery. The workshop consisted of a range of precision engineering machinery with the centrepiece being an exceptionally tidy Challenger VM-1300 vertical machining centre. The workshop also consisted of two conventional lathes, an exceptionally tidy MRF universal milling machine, a Yamage slotter, two surface grinders, and a cylindrical grinder along with all the usual welders, workbenches and other tools.

The Process

Skylarc visited the site and provided a complete valuation of all of Marks plant and machinery, providing a valuation with integrated photos of all major plant, along with estimated sale prices (low and high) to give a realistic expected sales value. This gave Mark the opportunity to analyse the return he would get from his assets and make an informed decision regarding their sale.

The auction set up took two weeks; All machinery was professionally groomed to a high standard and 312 lots were photographed and described. Video footage of machinery operating was included for all workshop machinery and their videos uploaded to YouTube for inclusion in the Trade Me listings.

Marketing

A comprehensive plan to sell all assets via an online Trade Me event was produced backed by a detailed marketing plan incorporating email outs to Skylarc’s own and engineering industry mailing lists, display advertising on Trade Me itself and a targeted Facebook campaign which reached over 38,000 people. A landing page featuring information about the auction was published in all marketing and this linked onto the auction once it was listed on Trade Me.

The Outcome

The auction ran for 7 days. Total sales exceeded the valuation by 43% with turnover significantly above expectations.

Collection was staged for better health and safety and customer service, with small items movable by hand collected over a three day period, followed by medium-sized machinery movable with a forklift and finally heavy machinery that required specialist equipment and disassembly. The site was cleared within a week.