![]()

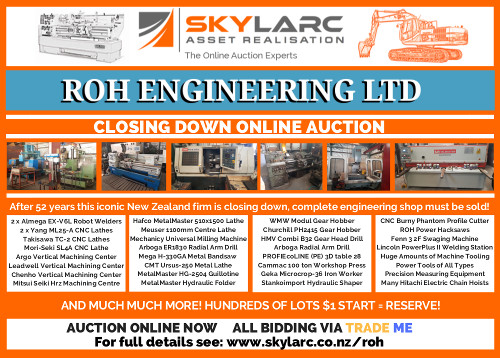

ROH Engineering is an iconic manufacturer, famous in New Zealand for their mechanical hacksaws still found throughout our nations’ workshops. ROH later went on to invent and manufacture a highly effective turf coring machine, exporting through major brands through the US and the world. Not happy to stop there, they moved on to building their own frost protection fans installed throughout New Zealand and Australia’s wine and fruit growing regions. However, at over 80-years old, it was time to retire. Skylarc provided the Rohleder family with a valuation for all plant and machinery, and a plan to sell the machinery in short order.